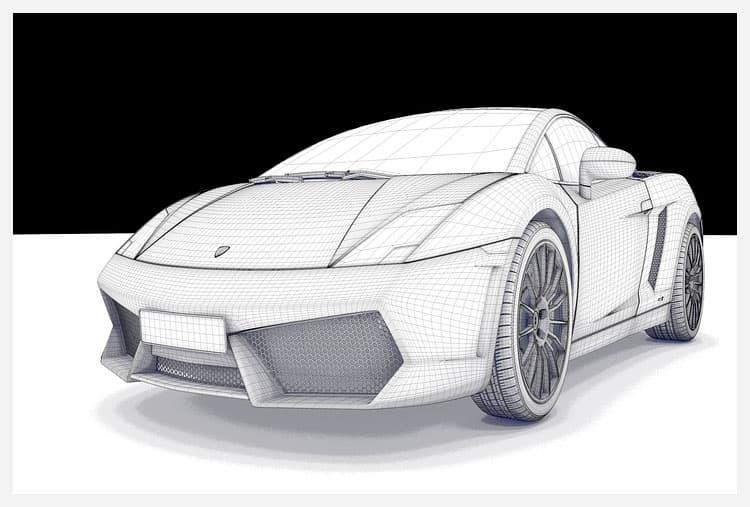

Finite Element Analysis (FEA)

At VMTL, we offer comprehensive Finite Element Analysis (FEA) services to help you analyze the structural integrity and performance of your parts and products. Our team of experienced engineers uses advanced FEA software and techniques to simulate how a part or product will behave under various conditions and identify potential issues.

Our FEA services include:

1. Structural Analysis - We can simulate how a part or product will behave under different loads, such as static, dynamic, and thermal loads. This allows us to identify potential failure points, optimize the design for strength and durability, and reduce the risk of costly failures.

2. Thermal Analysis - We can simulate how heat will affect a part or product and identify potential thermal issues such as thermal stresses, thermal expansion, and temperature distribution. This allows us to optimize the design for thermal performance and ensure that the part or product will operate safely under different temperature conditions.

3. Modal Analysis - We can simulate the natural frequencies and modes of vibration of a part or product and identify potential resonance and vibration issues. This allows us to optimize the design for stiffness and vibration damping and ensure that the part or product will operate smoothly and without excessive vibration.

Our FEA services are beneficial in many situations, including:

a. New Product Design - We can use FEA to optimize the design of a new product for strength, durability, and performance.

b. Failure Analysis - We can use FEA to identify the root cause of a failure and recommend corrective actions to prevent future failures.

c. Material Selection - We can use FEA to compare the performance of different materials and select the most suitable material for a particular application.

At VMTL, we pride ourselves on delivering accurate, reliable FEA solutions that meet your specific needs. Contact us today to learn more about our FEA services and how we can help you achieve your engineering goals.

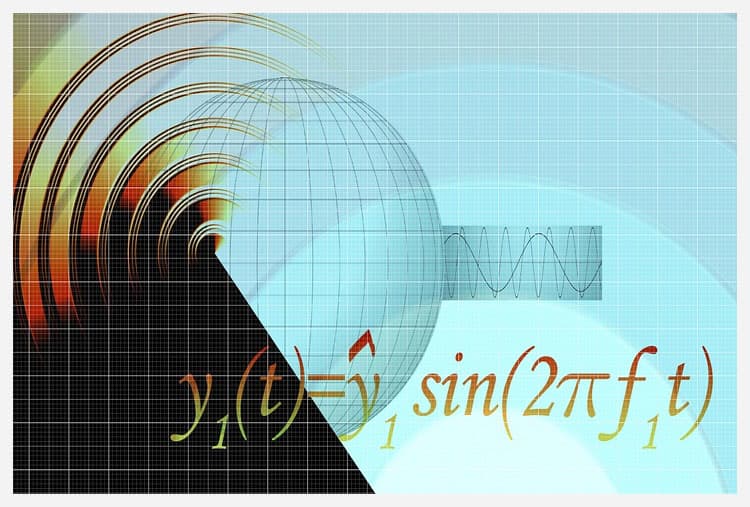

Computational Fluid Dynamics (CFD):

At VMTL, we offer comprehensive Computational Fluid Dynamics (CFD) services to help you optimize the performance of your parts and products that involve fluid flow. Our team of experienced engineers uses advanced CFD software and techniques to simulate how fluid will behave in a given geometry and identify potential issues.

Our CFD services include:

1. Fluid Flow Analysis - We can simulate how fluid will flow through a given geometry and identify potential issues such as turbulence, cavitation, and separation. This allows us to optimize the design for flow efficiency and reduce pressure drop and energy loss.

2. Heat Transfer Analysis - We can simulate how heat will transfer in a given geometry and identify potential issues such as hot spots, cold spots, and thermal stresses. This allows us to optimize the design for thermal performance and ensure that the part or product will operate safely under different temperature conditions.

3. Aerodynamic Analysis - We can simulate the aerodynamics of a part or product and identify potential issues such as drag, lift, and stability. This allows us to optimize the design for aerodynamic performance and ensure that the part or product will operate efficiently and without excessive turbulence.

Our CFD services are beneficial in many situations, including:

a. New Product Design - We can use CFD to optimize the design of a new product for flow efficiency, thermal performance, and aerodynamic performance.

b. Failure Analysis - We can use CFD to identify the root cause of a failure and recommend corrective actions to prevent future failures.

c. Performance Optimization - We can use CFD to optimize the performance of an existing product and improve its flow efficiency, thermal performance, and aerodynamic performance.

At VMTL, we pride ourselves on delivering accurate, reliable CFD solutions that meet your specific needs. Contact us today to learn more about our CFD services and how we can help you achieve your engineering goals.

Advanced CAE Analysis:

FEA and CFD are general applications of engineering analysis and it is the most basic need for a simple product. Due to innovation and highly complex manufacturing possibilities, there is a need for multi-physics solutions which required advanced CAE.

Our expertise have experience on multi-physics analysis like Fluid-Structure Interaction, Fluid-Thermal Cooling system, Vibro-Acoustic and Piezo electric functionality.

Looking for advanced and complex study of engineering physics to help build an innovative product, feel free to call us at +91 97890 99151 now.

For Support

VMTL has the best simulation software and skilled talent to provide accurate engineering simulation and analysis irrespective of the domain and industry. Contact us now to get a Quote by clickcing the contact us now. You can also review our completed projects to understand the quality of our work.